11-07 2022

Innovations boost advantages of monofilament machine

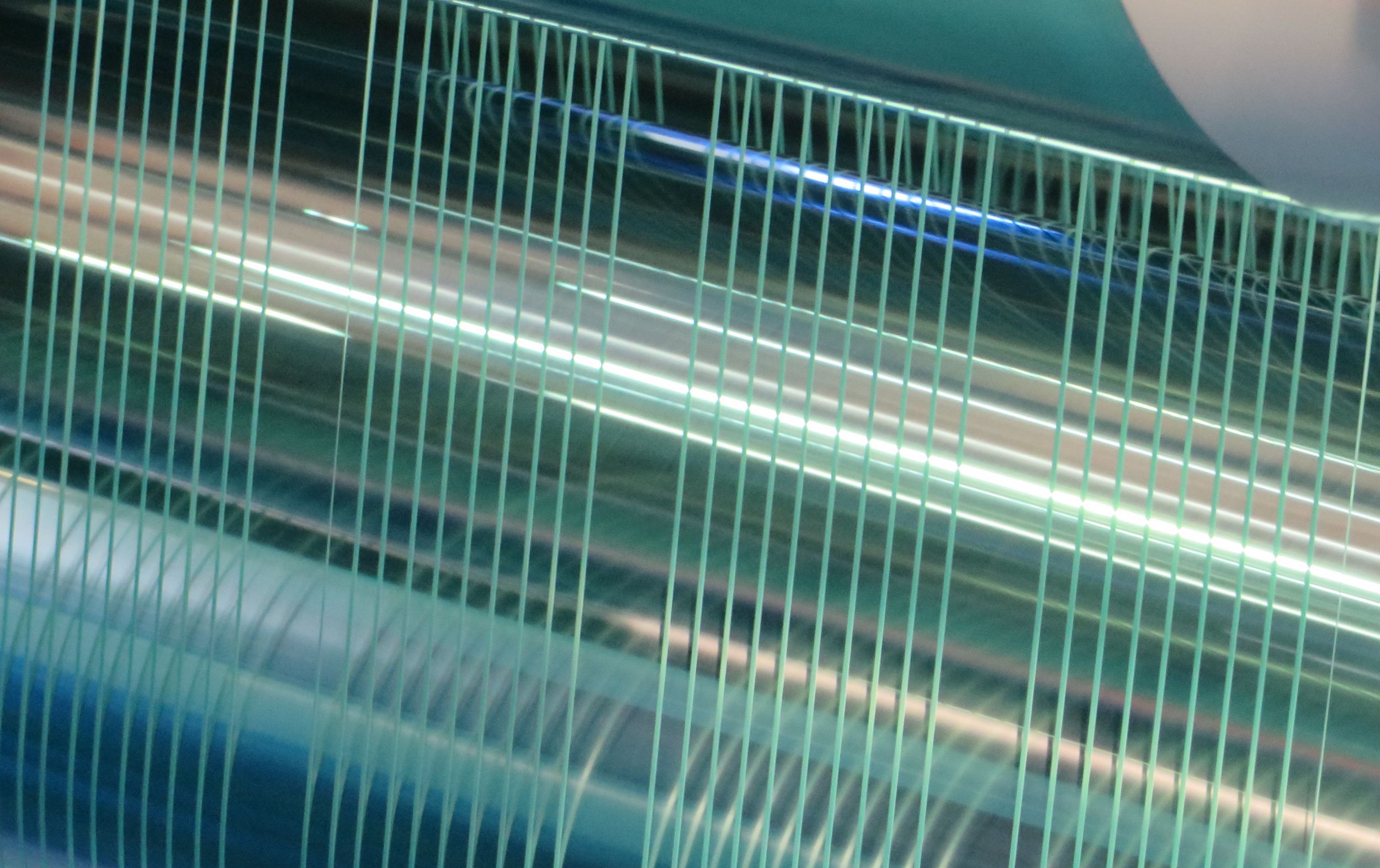

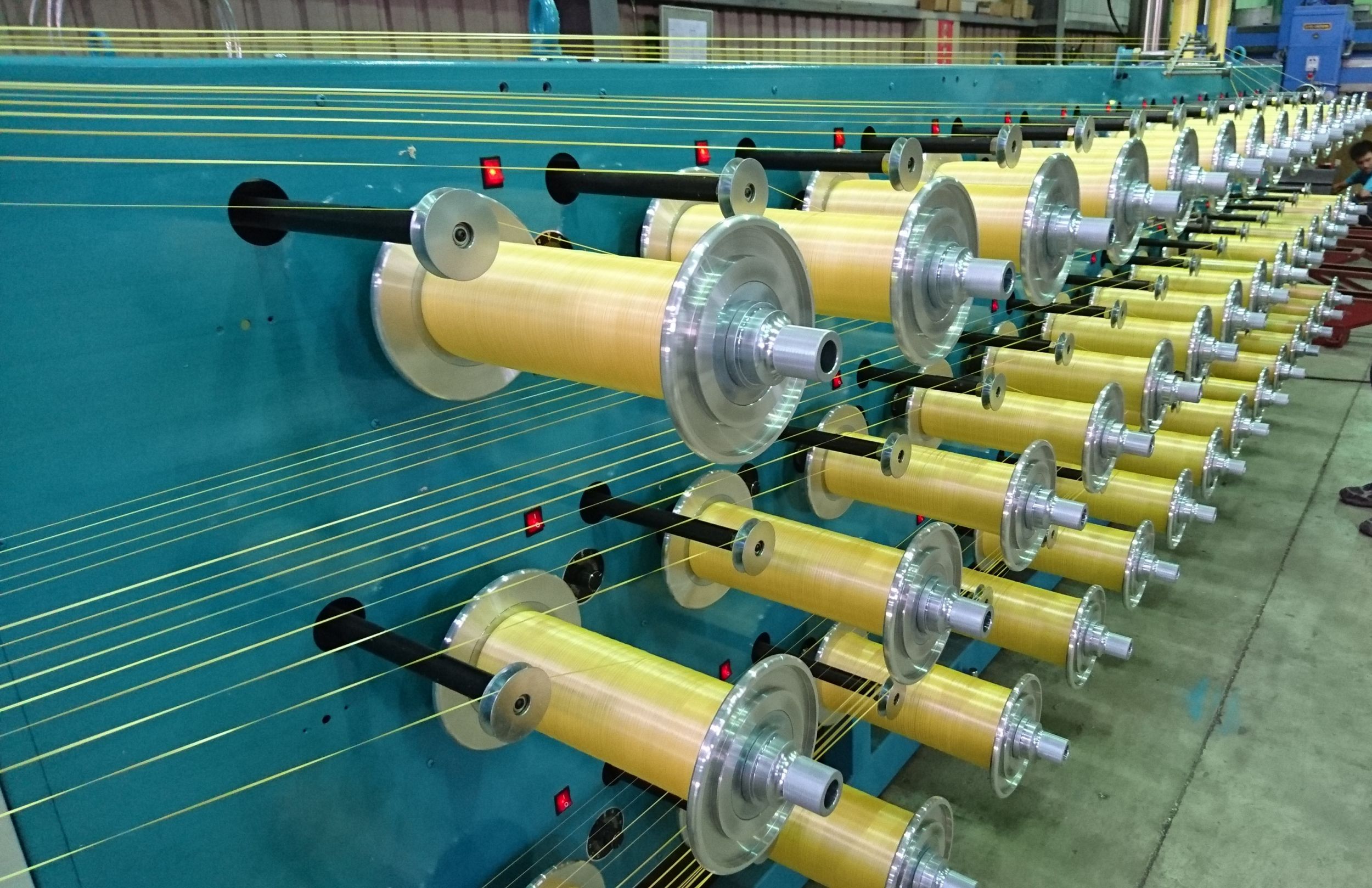

The secret to Diing Kuen's simple success is to never stop innovating. The semi-finished products produced by its monofilament machine are used in a wide range of industries. For example, in the aquaculture, fishing and ocean shipping industries, the fishing nets, fishing lines, cage culture, and ropes used in these industries require elasticity, toughness, and tensile force of at least 8-12 gpd; Diing Kuen's monofilament machines not only produce monofilaments of 8-12 gpd or more, but some Diing Kuen’s special monofilament machine models can produce up to 15 gpd. The tensile force of each fibre can be increased so if the customer compare two ropes of the same size, which can generally withstand 5 metric tonnes, Diing Kuen's equipment can produce special ropes that can withstand 10 metric tonnes.

The mechanical design of the Diing Kuen machine makes it stand above the rest. In order to meet the market's demand for 24-hour uninterrupted production, the equipment needs to operate at a high speed of 200-250 m/min. or even 400 m/min. during the production of monofilament, which highlights the importance of Diing Kuen's equipment for high stability and continuous yarn. Diing Kuen's machines enable customers to avoid raw materials wastage and save time and cost, thus creating high quality, improved precision and superior tensile force products.